Story and Photo by Russ Kaniuth

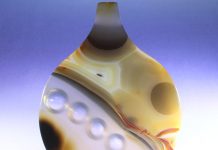

Metallic lapidary materials have always been extremely desirable, not only from a lapidary point of view, but also for jewelers. Josephine’s Crown quartz has a very elegant look to it, with its steamers of metallic colors, predominantly gold from its mix of pyrite and chalcopyrite. This material comes from southern Oregon and is composed of pyrite, chalcopyrite, and various sulfides mixed in white and black quartz. It is found in nearby gold and silver mines. It’s not unheard of to actually find trace amounts of gold in this material, as well.

Josephine’s Crown quartz is relatively hard (Mohs 5-6), since the main host rock is a fine-grained, high-silica quartz. However, since pyrite and chalcopyrite are much softer, a greater the amount of metallic material may make the stone seem as if it’s much softer. That is something to take into consideration when beginning to cab this material, as it will undercut if you don’t take precautions.

Slabbing this material is rather easy; there’s no real direction in which to cut, since the material will generally have the same look when cut from any direction.

Pay close attention when preforming your material to your cabochon shape. Try to keep most of the host material toward the edges and not very much of the pyrite; since it’s the softer portion of the material, you can easily lose your edge, and have it roll over and lose some of the girdle.

Begin on an 80-grit wheel to cut and dome your shape, then move on to the 220 grit stage. Here is where you will want to make the most out of shaping and doming your cab, and smooth it as much as possible before moving on. Working on the 220-grit wheel will remove material at a comparatively even rate, and that is most important because once you move on to the soft resin wheels, this is where the undercutting will start.

Undercutting is when two components mixed into the same material grind away unevenly due to different hardnesses, giving you a surface that’s not uniformly smooth. It is really important to continue to check your edges, making sure you didn’t hit any soft areas and round over too much in one portion of your girdle, and lose that uniform size all the way around your cab.

Once you feel you’ve achieved a smooth finish on your 220-grit wheel, move on to the 280 grit stage where you should go easy with a light hand to avoid any deep undercutting. Stop when you feel this stage is close to complete and dry off your cab and check for any deep scratches before moving on. If you see micro swirls within the gold metallic areas, this is usual for this stage and nothing to panic over, remember these are the softer areas and the other wheels will smooth this out as you go.

From this point on, finish out as you would any other cab; dry between stages and make sure you don’t go any farther if you find scratches. Finishing on a 14000-grit wheel will leave you with a beautiful and glossy finish; however, if you have a 50000-grit wheel, I highly suggest using it to enhance the metallic shine.

Once you’ve finished polishing on the diamond resin wheels, this material will take on an extra luster if you polish it with cerium oxide on a leather buff, and it will be all ready for a nice setting.