By Russ Kaniuth

Hornitos, California, is a mid-1800s Old Western gold mining town nestled in the rolling foothills just north of Mariposa and near Yosemite, and home to many varieties of orbicular jaspers. Hornitos has a vast BLM land area to rockhound in, much of it either has claims on it, or the area has been picked over pretty thoroughly over the years. Even though there’s not much to be found in nature anymore, it can still be found at rock shops, shows, and online.

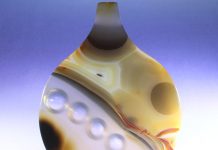

Hornitos poppy jasper is often mistaken for Morgan Hill poppy jasper. Though the locales are 125 miles apart, the combinations of red, orange, yellow, and white orbs are very similar. What is also similar is the fact that this jasper can be very fractured at times, which means cutting this material can have a few pitfalls.

When cutting this material from rough stone to slabs, it’s always best to rinse the material and look for any fracture zones in the stone. For best results, rinse off the material and take it into a well-lit area and watch as it dries. The surface will dry first, leaving moisture in the cracks and making more visible to the naked eye areas that you probably didn’t see a fracture before.

Generally, these fractures usually run in one direction. So before attempting to load the stone into your saw, you may want to find these fracture zones and cut along them in the same direction to get the most solid slabs. Among Morgan Hill, Stony Creek, and a few other California poppy jaspers, Hornitos usually is the most solid of them all, but bench testing each slab for fractures is always best before proceeding to cut your preform cabs on the trim saw. I usually try and flex each slab to see if there are any weak areas or fractures that aren’t visible. For the areas with cracks that are visible, I will try even harder to see if those will break off.

It’s better to find out if your material will break before starting the cabbing process then in the middle after you have put a significant amount of work into your piece.

When starting to cab this material, be cautious of using course grit wheels. Starting on an 80 grit should be OK, but be gentle when shaping your preform as it will tend to chip the outer back edge. Once you have shaped your cab on the 80 grit wheel and started the dome, I usually suggest a 180 grit steel diamond wheel, then move to a 220 soft resin, or 280 if that’s what your set-up is. The 180 grit steel will easily remove deep scratches and will grind smoothly. Then by moving onto a 220 soft resin wheel instead of steel, it will smooth the cab completely out and remove all remaining scratches and any flat spots that may have been left from the steel wheels. After this stage, moving onto the soft resin 280 grit wheel will be used to sand smooth and be the start of the polishing process rather than the sanding process.

From this point on, continue your usual process. For most set-ups, which usually end at 14k grit wheels, this will leave you with a beautifully polished poppy jasper cab. However, I personally like to go one step further to a 50k grit wheel to obtain the highest polish I can. Polishing any further with compounds will work, but there may be small pits in this material, and cerium oxide will fill in these spots and not leave an achieved look, so finishing on the resin wheels is usually preferred.

Author: Russ Kaniuth

Is the owner of Sunset Ridge Lapidary Arts and the cofounder of the Cabs and Slabs Facebook group. View more of his work at www.sunsetridgelapidary.com.

Is the owner of Sunset Ridge Lapidary Arts and the cofounder of the Cabs and Slabs Facebook group. View more of his work at www.sunsetridgelapidary.com.