By Bob Rush

Seeing what you are doing while making a cabochon is as important as what you are doing with your hands and the machine you are using. It’s not only the brightness of your lights, but the type of light you are using that makes a significant difference in the quality of your work.

At my workplace, I use a long reach goose-neck style lamp. The best source for the lamp, in my opinion, is the popular Swedish home furnishings store. They call them luminaires. They come with a small wattage bulb that will not work for our purposes.

Selecting the Best Lighting for The Job and Space

Most new lighting comes with LED lamps, but they give out a diffused light, which is bright, but you can’t see details about the cab’s surface. In the past, I used clear 100-watt bulbs because they give out a spot of light that reflects off the surface and exposes the scratches and flat spots. Unfortunately, they are no longer available. As a replacement, I went to a clear 100-watt halogen bulb. These are difficult to find now, but it is possible to find them from time to time, for as little as $2 each. This type of bulb gives off a spotlight. One of the best sources of a spot-type light is the sun when it is available.

The next type of light that I find very valuable for detecting flat spots and contours on the top of the cab is a standard two-bulb four-foot fluorescent light fixture. I’ve mounted it on the ceiling with the bulbs aligned right-to-left in my workspace to reflect two parallel white lines across the cab’s surface.

The next type of light that I find very valuable for detecting flat spots and contours on the top of the cab is a standard two-bulb four-foot fluorescent light fixture. I’ve mounted it on the ceiling with the bulbs aligned right-to-left in my workspace to reflect two parallel white lines across the cab’s surface.

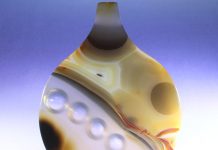

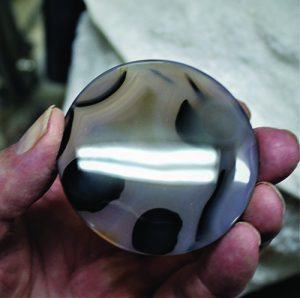

Now let’s look at how lighting makes a difference. When working on a cab, and you have finished the grinding and are starting the sanding process, you can hold the cab in front and look at the two reflected lights. Ideally, you should see two parallel lines of light as you rock the cabochon back and forth.

Most likely, the lines will be jagged because of the flat spots remaining from the grinding steps. As you continue with sanding these flat spots, be sure to continue checking the reflections. When you see two straight lines, you have succeeded in removing the flat spots.

Lighting Aids in Checking Surface Condition

The next cabbing step is to remove the large flat spot in the center of the cab if you are intending on having a continuous dome across the top of your cab. I use a very coarse (80 to 100 grit) belt to sand the flat spot out. You want the two reflected lines to remain parallel across the top of the cab. This indicates that you have successfully removed the flat spot.

I also use the parallel light reflections to check that the top outer surfaces are smooth all the way to the edge of the cab. Any ripple will show up easily.

My final step occurs at my photo station. It has two LED spotlights. I shine one from the side to do the overall lighting and the other a little to the front, so I get a slight reflection on the edge. This is to indicate the quality of the polish.

Author: Bob Rush

Bob Rush has worked in lapidary since 1958 and metal work and jewelry since 1972.

Bob Rush has worked in lapidary since 1958 and metal work and jewelry since 1972.

He teaches at clubs and Modesto Junior College. Contact him at rocksbob@sbcglobal.net.