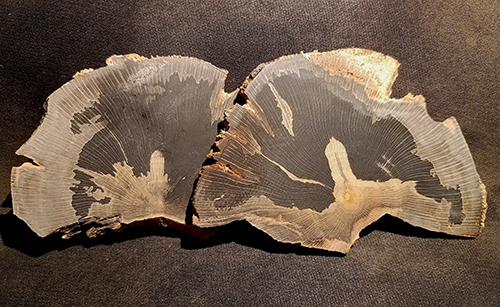

Sycamore petrified wood is one of the darker petrified woods. Unlike other varieties that are opalized and riddled with fractures, it is easier to work with. In materials like Blue Forest and Eden Valley petrified woods from Wyoming, much of the ring pattern still shows; however, most of the nicer sycamore comes from Oregon, near Sweethome.

Working With High-Contrast Rings

Sycamore petrified wood, in my opinion, is one of the more beautiful varieties because of its black color and high-contrast tree rings. Other petrified wood materials include Hell’s Canyon and Teredo. I recently learned a new technique from Roy Kessell, of R&B Rockshop, for prepping this material before cabbing it.

Once you get your slabs cut, you may think you have found some nice areas that will make good cabs; however, much is hidden in the black areas. Roy showed me that you can soak the slabs in bleach for two to three days to expose more of the tree ring patterns. This method is to be used to each person’s personal preference, so soak your slabs and check them each day.

Take them out, thoroughly wash them off and give them an hour to completely dry to see exactly how it looks. If you don’t get the desired look on the first or second day, put the stone back into the bleach, let it soak another day, and check again.

Take them out, thoroughly wash them off and give them an hour to completely dry to see exactly how it looks. If you don’t get the desired look on the first or second day, put the stone back into the bleach, let it soak another day, and check again.

Once you’ve achieved the contrasting pattern you are looking for, start trimming out your preforms and start the cabbing process. Sycamore isn’t extremely hard; I’d say it’s about 5.5 to 6 on the Mohs Scale of Hardness, and rather easy to cab. Take your usual steps in the cabbing process and start to shape your cab on an 80 grit wheel. Once you have gone past the 220 up to the 280, dry your cab off and let it sit out, allowing it to completely dry before moving on.

Cabbing Sycamore Petrified Wood

This is where you need to recheck the pattern to see if you have ground off too much of the bleached pattern you prepped earlier. In a lot of cases, the bleach will only go so deep, and by the time I finished the 280 grit wheel, I had lost a lot of the contrasting colors I was looking for and had to go soak the cab in bleach for an additional day to get the desired pattern back. At this point, it’s safe to finish the cab through the rest of your cabbing process and not have to worry about any color changes.

When cabbing these types of black petrified woods, always dry the piece off after each stage and check for any white, hazing type of spots; this is where micro scratches are still showing and will continue to show unless you go back a step and make sure to get them completely out.

This is very important after completing the 600 grit stage. Not only dry off your cab with a towel but allow it a few minutes to air dry and check for any hazy spots or scratches.

The finishing process is fairly easy, even if your machine only goes up to 14000 grit; this should yield and very glossy finish. However, if you go as far as 50000 grit, you will definitely obtain a mirror finish and not have to go any further with polishing compounds. If you choose to use cerium oxide as your finishing polish, be sure to have a bowl of warm water and a toothbrush available to get out any polishing compound that may stick in crevices.

This What to Cut column about sycamore petrified wood previously appeared in Rock & Gem magazine. Click here to subscribe! Story by Russ Kaniuth.