By Russ Kaniuth

Caldera Paint Jasper is another great find from the McDermitt area on the Oregon side of the border. Gary Green jasper was originally found in this area by Gary McIntosh and Ray Larson, but later Caldera Paint jasper was discovered. It went unnamed and was ignored at the time because everyone was after the Gary Green.

By the 1960’s Reggie Kemp starting digging the Caldera Paint jasper. Because it was mostly surface material, and the focus was still very much after the green, it was set aside for another day.

Digging Deep to Yield More Jasper

In the spring of 2018, on land now owned by Dale Huett, Reggie and Aaron Buell started excavating a newer batch of the Caldera Paint, at a much greater depth of about 16 feet, which yielded a more solid, pit-free material that was far more worthy for lapidary use.

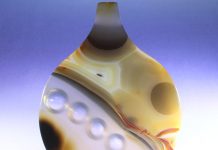

Caldera Paint jasper has all the same patterns and features as Gary Green jasper, but the colorations are completely different. This material is rich in the southwest themed colors with bright waves of orange, red, yellow, browns and black. It very much has the look and feel of a petrified wood, even though it’s a jasper.

Caldera Paint jasper has all the same patterns and features as Gary Green jasper, but the colorations are completely different. This material is rich in the southwest themed colors with bright waves of orange, red, yellow, browns and black. It very much has the look and feel of a petrified wood, even though it’s a jasper.

Slabbing this material is very much the same as Gary Green, and many other jaspers. Starting off, wash the material and brush off what you can to expose the patterns and waves to determine the direction you want to cut. Many times if you cut against the grain, you can obtain the waves of colors. By cutting with the grain patterns you might get more of a puddle of colors look.

Basic Process Works Best

The cabbing process is rather simple and regular to most jaspers. However, Caldera Paint and Gary Green are relatively hard, so starting on an 60-80 grit wheel is advised.

One thing I like to do when cabbing hard jaspers is adding a 180 grit wheel to my set up. With this I can rough out my preform shapes on a 60 grit wheel and continue to smooth out the dome on the 80 grit wheel, and ultimately use the 180 to remove any deep scratches before moving on. Most people still tend to use a 220 steel wheel, and again, here’s where I switched and changed that out for a 220 soft resin Nova wheel.

The 60-80 will shape nicely while the 180 removes deep scratches and the 220 soft resin will smooth it out very fast, leaving very little work for the 280 grit wheel.

Once I have finished on the 280 grit, I like to keep a can of air handy, and blow dry it quickly and double check for any scratches before moving on. At this point you will see the material start to polish up nicely, even on the 600 grit wheel. Continue your normal method of cabbing, usually up to a 14k grit wheel, and you will certainly appreciate the way Caldera Paint takes a nice polish!

Getting a Shine, Naturally

Since this material polishes up so nice on it’s own, I generally wouldn’t use any polishing compounds on it to try and polish it any further. However, if you like to obtain that mirror polish, cerium oxide and a leather wheel can be used.

I had such a great time working with this material, I hope you enjoy it as much as I did.

This material is readily available at the Caldera Rock Shop in McDermitt, along with all types of other superb materials. The shop is located at 650 Lasa Dr, McDermitt, NV. Plus, you can always order online by contacting Leanne Kemp at rockcandymt@hotmail.com or 503-495-3087.

Author: Russ Kaniuth

Is the owner of Sunset Ridge Lapidary Arts and the founder and overseer of the Cabs and Slabs Facebook group.

Is the owner of Sunset Ridge Lapidary Arts and the founder and overseer of the Cabs and Slabs Facebook group.

View more of his work at www.sunsetridgelapidary.com.