By Steve Voynick

If Minnesota ever decides to designate an official state rock, it should be banded iron ore. Since the late 1800s, Minnesota’s four “iron ranges” have yielded four billion tons of banded iron ore that have provided 90 percent of the nation’s iron.

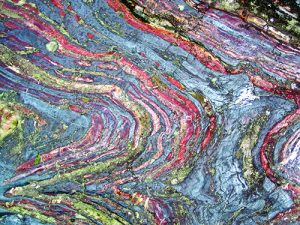

The two types of Minnesota’s banded iron ore are specularite and taconite. Specularite is a high-grade ore with well-defined, alternating layers of reddish chert and dark, glittery hematite; taconite has dark-gray bands and is much lower in grade. They share a common origin and are among the oldest ores ever mined.

Two Banded Ore StandOuts

Both specularite and taconite are partially altered sedimentary rocks. They were laid down during the late Precambrian Era when the Earth’s atmosphere was devoid of oxygen. The region that is now northeastern Minnesota was then covered by a warm, highly acidic, shallow sea rich in dissolved iron and silica.

(Photo by Steve Voynick)

Some 2.5 billion years ago, global environmental conditions began changing with the onset of the Great Oxygenation Event, a sweeping biochemical transition that lasted more than a billion years. It was triggered by the appearance of cyanobacteria, simple, algae-like life forms that obtained energy from photosynthesis and released large quantities of oxygen.

Thick layers of cyanobacteria formed reef-like structures (which fossilized as stromatolites) at the edges of the seas. Cyanobacteria oxygenated the seawater, slowly reducing its acidity and precipitating iron ions as magnetite (ferric-ferrous oxide, Fe3O4) and silicon ions as chert (microcrystalline quartz, SiO2). After the iron had precipitated, excess oxygen then began escaping from the seawater to eventually create the oxygen-rich atmosphere that we breathe today.

Iron and silica accumulated on the sea bottom as alternating layers of magnetite and chert. The heat and pressure of deep burial later lithified these sediments into a hard, durable rock containing 25 percent iron. Much later, meteoric water and hydrothermal fluids altered part, but not all, of this iron-rich rock.

Altered Layering At Work

Within the altered sections, magnetite oxidized into hematite (ferric oxide, Fe2O3). Large amounts of silica also leached away, enriching the rock’s iron content to 55 percent. Because crystalline hematite is silvery-black and particulate hematite is red, this altered, iron-enriched rock exhibits alternating layers of reddish chert and shiny gray layers of crystalline hematite.

The unaltered sediments formed taconite, a hard, a high-silica, dark-gray rock that

(Photo courtesy Bjoertvedt/Wikimedia Commons)

consists of magnetite and chert, and contains about 25 percent iron.

In the 1800s, Minnesota’s first iron miners were concerned only with the high-grade specularite that required no concentration and could be shipped directly to distant smelters. But when the specularite ran out in the 1950s, Minnesota’s iron-mining industry faced a crisis. All it had left was huge quantities of taconite—all too low in grade for direct smelting.

U of Minnesota’s Transformative Studies

In the 1920s, the University of Minnesota’s Dr. Edward W. Davis, aware that the reserves of high-grade specularite wouldn’t last forever, had begun studying ways to concentrate low-grade taconite. After decades of work—and just as the specularite was being depleted—he perfected an inexpensive process to “pelletize” taconite. Grinding it to a powder, he concentrated its contained magnetite with electromagnets, added powdered limestone and bentonite clay, then rolled the mixture into half-inch pellets and roasted it at high temperatures.

This exothermic reaction, which provided much of the process’s required heat, oxidized the magnetite into hematite and yielded hard porous pellets. Produced at mine sites, these ready-to-smelt taconite pellets contain 55 percent iron—high enough in grade to be shipped to distant smelters.

Pelletization saved Minnesota’s iron-mining industry. Today, six Minnesota mines pelletize 40 million tons of taconite ore worth $1.5 billion each year. So, if Minnesota ever designates an official state rock, it should be either specularite or taconite, or simply “banded iron ore.”