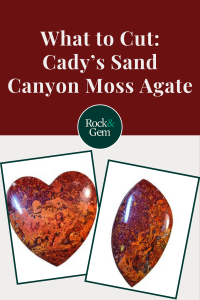

Cady’s Sand Canyon Moss Agate is a variety of moss agate with a unique blended moss and plume pattern with red and orange as its dominant colors.

In Southern California, amid the Mojave Desert, people have been prospecting agates out of the Cady’s Mountains for decades. There are plume agates, flame agates and a variety of moss agates to be found. What are agates? Each is unique with its own characteristics and color schemes.

A New Find

Recently I received a parcel of Sand Canyon Moss agate from Martin Kramer, who has been prospecting that area for many years. He’s informed me that many of the roads inside the Cady’s have now been closed to the public. Many of the collection areas for rockhounds are now closed. Martin did come across a new variety of Moss agate from the Sand Canyon area before the area closed.

This moss agate has a unique blended moss and plume pattern tightly combined with red and orange as its predominant colors.

Purchasing Material

Though this material isn’t the easiest to find in the marketplace, you can access some by contacting Martin Kramer directly via the Facebook group The Slab Depot.

When purchasing rough, it’s not always easy to see what is inside because of its ashy tuft outer layer. Still, usually one end or another will have a window broken off from the mining process. From this, you can get an idea of what directions the patterns are going.

When purchasing rough, it’s not always easy to see what is inside because of its ashy tuft outer layer. Still, usually one end or another will have a window broken off from the mining process. From this, you can get an idea of what directions the patterns are going.

If you see any green, that is just a thin layer of color that borders the outer edges and won’t be part of the inner core pattern.

Sometimes it might be best to buy slabs if you are concerned about the coloration or pattern. If you choose to buy rough, there’s no right or wrong angle at which to cut, but most Cady materials do run in seams and leave you with a flat top and bottom. This is quite helpful to clamp your vice down on to start cutting your slabs.

Preparing for Cabbing

Once you have your slabs cut, this is a good time to examine and possibly prepare the slabs for cabbing. Though this material is generally quite solid, it could tend to have a few natural pits here and there throughout the material.

Many people enjoy the natural way the stone is and will cab as such, while others want a complete uniform surface on their cabs as a finished product. If that is the case, here is where you can stop and stabilize your material in a vacuum chamber, or if it’s just ever so slightly pitted, you can fill it with epoxy that is thinned out with a touch of acetone.

Filling in the Gaps

Many times, by filling in natural vugs, pits, fractures, etc., it may not stand up to the cabbing process and may slightly undercut. This outcome is something to be aware of so that you can examine your cab around the 280 grit stage to see if it’s looking good or if you need to stop and add another layer of epoxy before moving forward. If any alterations to slabs or cabs are used, this should be disclaimed when selling the finished cabochon.

Cabbing

Once you are ready to cab, it’s pretty straightforward to work this material like any other type of agate or dense jasper.

Sand Canyon Moss agate is approximately a 6 on the Moh’s Scale and won’t generally break, but it will tend to chip on the outer back edges of the course 80 grit wheel when shaping out your preform cabochon. This result is not something to be overly cautious about, as it can be easily corrected as you sand and polish the back and girdle along the way.

Sand Canyon Moss agate is approximately a 6 on the Moh’s Scale and won’t generally break, but it will tend to chip on the outer back edges of the course 80 grit wheel when shaping out your preform cabochon. This result is not something to be overly cautious about, as it can be easily corrected as you sand and polish the back and girdle along the way.

Start on the 80 grit steel wheel, get your shape and dome started, and move along to either a 140 soft resin diamond wheel or 220 steel wheel to finish doming and take out all the deep scratches.

From that point, continue to your 280 soft resin diamond grit wheel and sand it down to where it’s starting to show a polish, and focus on making sure you don’t go any further if there are any remaining scratches. This is the point where you really need to dry it thoroughly, either with a towel, or my favorite, a can of air, and give it a quick blast.

Continue down through your polishing wheels, and you will notice a beautiful mirror polish upon finishing on the 14k grit wheel. At this point, you can certainly call this a finished product; however, if you’d like to achieve slightly more of a mirror finish, you can polish using cerium oxide on a leather buffing wheel. In the end, you’ll have a beautiful fire-colored moss agate cab like no other!

This What to Cut: Cady’s Sand Canyon Moss Agate previously appeared in Rock & Gem magazine. Click here to subscribe! Story by Russ Kaniuth.